Advanced Manufacturing

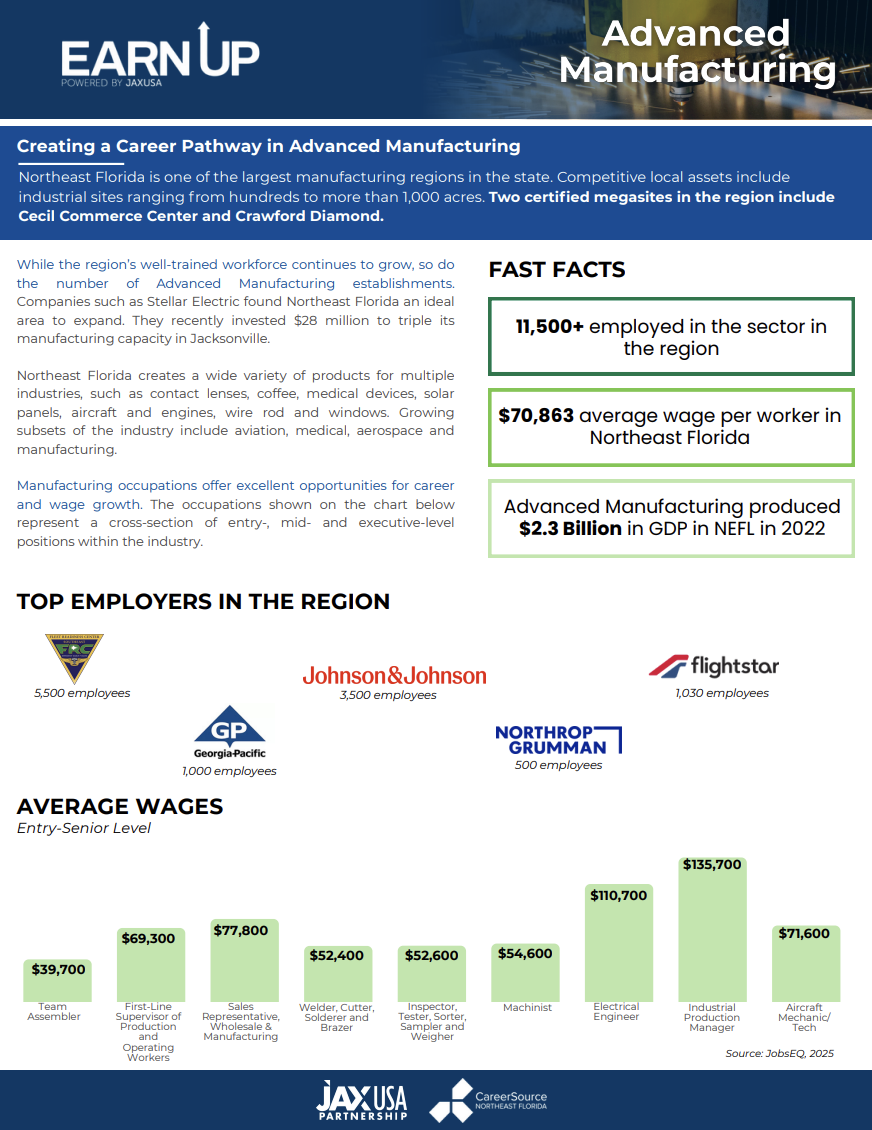

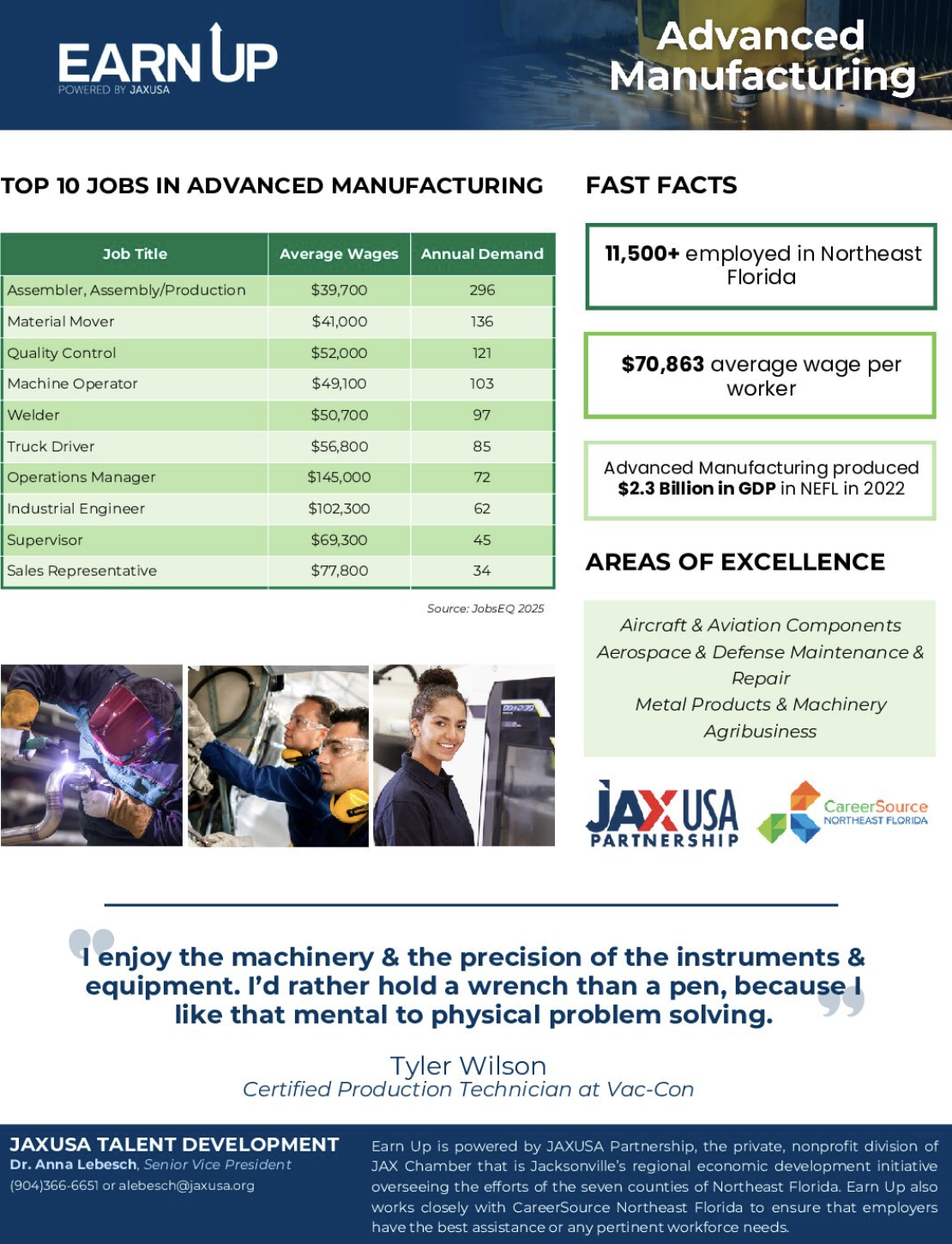

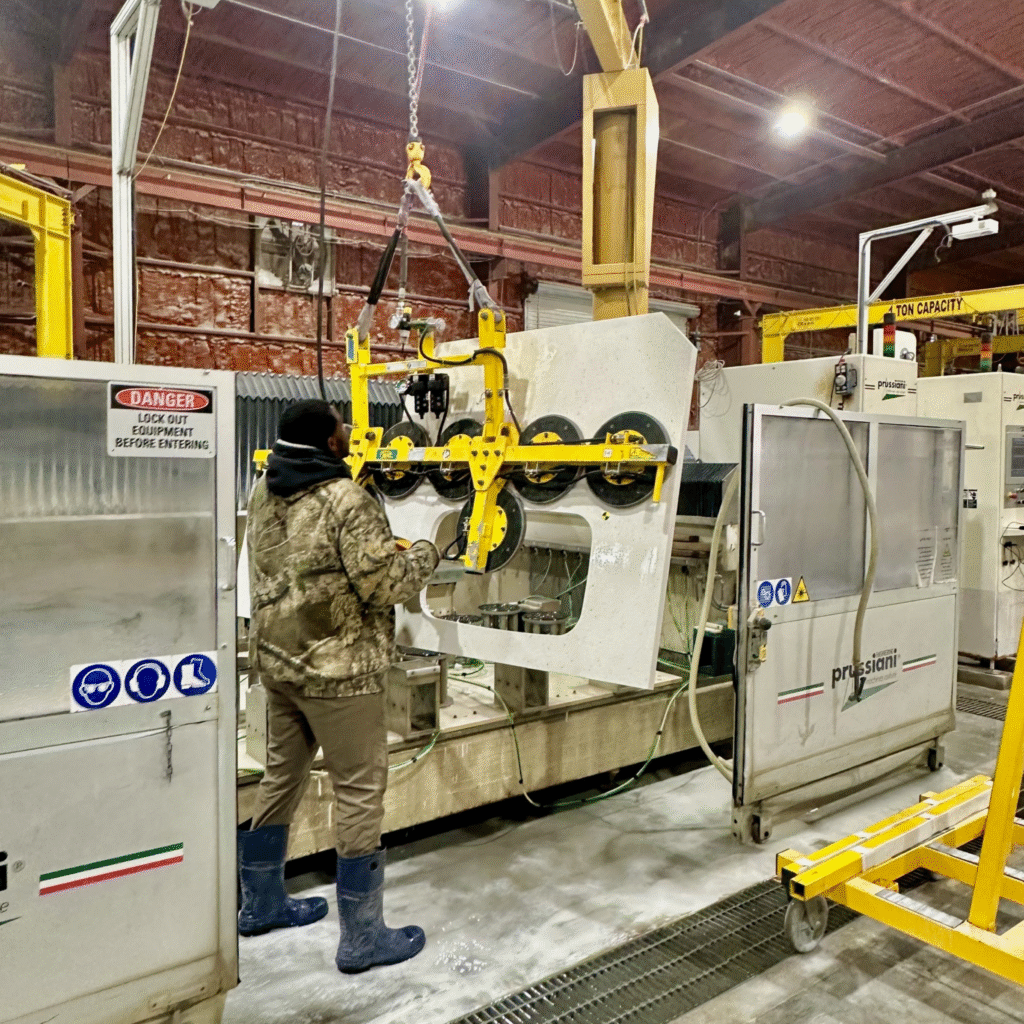

With industrial sites ranging from hundreds to more than a thousand acres, including two certified mega sites and a skilled, talented workforce, the Jacksonville region has proven its suitability for advanced manufacturing. As a result, many different types of products are made here, including coffee, contact lenses, aircraft and engines, medical devices, solar panels, wire rod, animatronics, windows, tactical armor, and batteries.